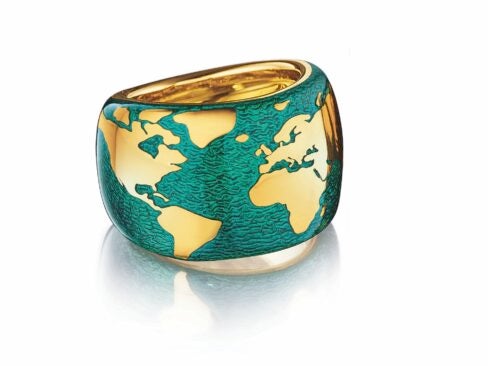

“It starts with the stone,” Moti Ferder, founder of Lugano Diamonds, explains. Ferder launched the Newport Beach-based brand in 2004 with his wife Idit, who sits on the board as COO, with the aim of not just creating fine jewelry, but a community for those who buy it, too. Tactile, multifunctional and intriguing — despite the value, Lugano pieces are intended to be picked up, worn, touched and loved. There are no white gloves in a Lugano showroom. “My philosophy is that jewelry should be worn,” Ferder says. “So the combination of having a three-carat pink diamond… which in many places would be a big deal… putting in ebony [hardwood] completely tones it down and makes it fun.”

And how do these pieces come to life? “We start by thinking, ‘[How can] we make the best of a stone? How would someone use it, how can we get the most value out of it?’” Ferder says.

From here, he gets to work. With a family background in Antwerp’s diamond industry, Ferder was born into the business and went on to undergo gemologist training. Despite being CEO of the international organization (there are seven stores — or ‘salons’ in Lugano lingo — in the States, and a new one over in London) he still has a heavy hand in the creation process and personally oversees the small team of designers, as well as the extended line up of craftspeople, which totals 16.

The Creative Process

Unusual for a US jewelry brand, the entire process, from design to completion, takes place under one roof in Lugano’s Newport Beach HQ. “It’s almost like a pharmacy,” Ferder says, describing the brand’s main workshop. “Typically, [jewelry workshops] are not very appealing places… they’re dirty and scruffy. In our workshop, everything is white and squeaky clean. They all sit there with their microscopes — it’s quite an incredible environment.”

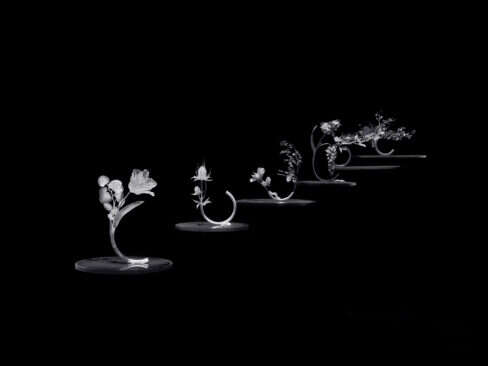

While the stone is the starting point for each piece, Ferder thinks about his clients from the get-go: “I start with a vision of, ‘how is it going to be worn? Is it bringing something new and different?’ You don’t invent the wheel for every single piece, but what really differentiates Lugano from other brands is the evolution. We’re creating about 150 new pieces every month, so the evolution is quite rapid, and you’re constantly learning and evolving and bringing something new,” Ferder explains. Sometimes the designs come straight from Ferder’s hands, others, it’s his direct instructions that end up creating the design: “I sit with the design and production team and give them instructions of what I want.”

From here, 3D mockups are created before the final design is handed over to a jeweler. “We choose who is the craftsman for every piece,” Ferder says. “Each one of them has different things that they’re great at. We have a lead for every piece, and based on their skill set, we can decide who’s going to execute it. For every jeweler there is some element of artistic touch that they add, and you can tell the finish between one and another.” While a lead jeweler is chosen for each project, a piece might pass through 10 hands before it’s ready. The individuality of Lugano’s jewelry also means that there’s no exact time frame for creating pieces: “We have a sense of what the labor should cost but we don’t have a set time… one could take 10 hours, something else could take 300 hours. There are some projects that take a year to do. Because of the experience of the team, it’s just intuitive.”

While Lugano’s stamp is on each piece that leaves the Newport Beach workshop, to Ferder, the most important story around a necklace, a ring, a bracelet is the person wearing it. “It’s about telling your story, not the brand story,” he explains. Pieces often have secret details included that might only be known to the wearer, and not visible when worn, such as a hidden gemstone on the inside of a bracelet or the back of a pair of earrings. “There’s always a surprise in there,” Ferder says.To Lugano, the marker of a ‘successful’ piece of jewelry is really how a client feels when wearing it. “I can tell you from my wife, when she puts a piece on, she doesn’t need a mirror. She puts something on and she knows if it’s good or not. When you feel it’s right, it’s right. I see that reaction with women trying on [our jewelry] a lot.”

Clients are often surprised by the backlog of pieces, too. “We had one customer, and it was her first time with the brand, and she was shocked at the depth, and the different materials and the different way of doing things. She tried on maybe 50 pieces, but we have more than 5,000 unique pieces in the company,” Ferder says. “This depth helps create inspiration as to why to even buy jewelry. It’s a differentiating factor and something that clients really appreciate.”

In fact, making the jewelry is only a small fraction of the Lugano process — the real process comes when they’re ready to be bought. The brand’s ‘salons’ are less retail space, more like the home of a friend; you’ll often find no jewelry on display at all. “We actually changed what return on investment meant to us,” Ferder explains. “For us, it’s ‘relationship, opportunity, inspiration.’ I would say that nine times out of ten, [a client has] no idea what to expect — and the element is creating the inspiration.”